Coal | Power Generation | AMETEK Land

Coal is one of the primary sources of fuel for power generation across the world. AMETEK Land supplies solutions for process control, efficiency, safety and emissions monitoring.

WhatsApp)

WhatsApp)

Coal is one of the primary sources of fuel for power generation across the world. AMETEK Land supplies solutions for process control, efficiency, safety and emissions monitoring.

Coal Mill In Power Generation. energy production and generation of coal power plant coal . Power Generation from Coal International Energy Coal is the biggest single source of energy for electricity production . Types Of Coal Mill In Power Plant. Get Price And Support Online; PRB Coal Users'' Group Sessions Electric Power 2018

These allow more electricity to be produced from less coal known as improving the thermal efficiency of the power station. Efficiency gains in electricity generation from coalfired power stations will play a crucial part in reducing CO2 emissions at a global level.

Coal fired power plants are a type of power plant that make use of the combustion of coal in order to generate use provides around 40% of the world''s electricity and they are primarily used in developing countries. Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal ...

Coal Fired Power Generation Equipment; ... Shanghai Electric Heavy Industry Group produces a range of basic products, such as metallurgic and rolling mill machinery, grinding equipment for power plants, mining cementing equipment, largesized forging pressing equipment and other heavy machinery. Our company was honored as Famousbrand ...

ConditionBased Maintenance Bolsters the Bottom Line in Power Generation ... On the left is a typical Alstom Power mill, on the right an MPS89 of similar capacity. ... Pulverized coal mills .

highefficiency power generation system, which significantly decreases the cost of power generation and CO 2 emissions, compared with conventional lignitefired power generation systems. Kobe Steel conducted research entitled the "Low CO 2 Emission Type Power Generation Project based on Upgraded 2Brown Coal (UBC) in India," ) which

We specialize in coal mills: in particular performance upgrades to meet the increasing demands on South Africa''s power generation industry. We provide a comprehensive service for major milling plant modifications, including investigations, feasibility studies, design, manufacture, installation and .

Our applicationspecific Millwatch CO monitor is recommended as the ideal solution for early warning of spontaneous combustion in coal and biomass mills.

This paper proposes an ammonia–water Kalina cycle driven by lowgrade waste energy released from the combustion reactions of mill''s rejection which is coupled with 500 MW e coalfired thermal power plant to quantify the additional electrical power. Energy of combustion for mill rejection is computed by combustion modeling equations.

New Control Strategies Improve Boiler Dynamic Response "This article provide a new control strategy to improve dynamic response for steam generator at CoalFired power plant, it provide a case study and explain the results for dynamic response"

Duke Energy has been using coal to produce electricity in the Carolinas since 1911. Those first coalfired plants (in Greensboro,, and Greenville, ) only supplemented the company''s use of hydroelectricity. In the 1920s, the growing demand for electricity began to outstrip the availability of hydroelectric generation.

South Africa''s coal reserves are estimated at 53 billion tonnes, and with our present production rate there should be almost 200 years of coal supply left. Producing electricity from coal starts when the coal is pulverised in huge mills into a fine powder before it is blown into huge kettles, called boilers.

A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection. ... With recently increased penetration of renewable power generation, coalfired power stations are required to operate more flexibly to serve as peaking load generation plants, to work with more varied coal specifications and to regularly add ...

South Africa''s coal reserves are estimated at 53 billion tonnes, and with our present production rate there should be almost 200 years of coal supply left. Producing electricity from coal starts when the coal is pulverised in huge mills into a fine powder before it is .

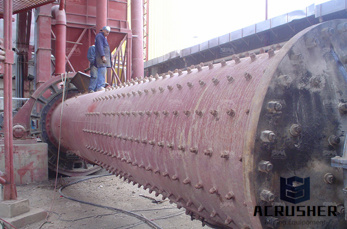

Coal fired power generation products. Bradken is a major supplier of grinding elements, mill liners and wear protection products used in coal fired power generation around the globe. With the understanding that power stations have unique conditions, we work with customers to customize wear elements to achieve optimum performance and part life ...

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in the cement industry.

Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power...

Oct 09, 2016· PULVERIZING PLANT / COAL MILL: In modern thermal power generation plants in order to achieve maximum burning efficiency coal is pulverized or ground in order to mix it with the hot air and then feeding to furnace in a stream of hot air. This helps increasing the surface area of the coal to action of oxygen and consequently helping combustion.

ConditionBased Maintenance Bolsters the Bottom Line in Power Generation ... On the left is a typical Alstom Power mill, on the right an MPS89 of similar capacity. ... Pulverized coal mills with ...

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

NewPage Luke Mill Power Plant. From SourceWatch. Jump to navigation Jump to search. Luke Mill Power Plant is a retired coalfired power station in Luke, Maryland. The plant provides power to the Luke pulp paper mill. The plant''s two coalfired units were retired in .

Apr 04, 2017· Metallurgical coal or coking coal is used in the process of creating coke necessary for iron and steelmaking. Coke is a porous, hard black rock of concentrated carbon that is created by heating bituminous coal without air to extremely high temper...

Pulverized fuel ash is formed during the process of combustion of pulverised coal in the furnace of the power station''s boiler. The coal is ground to powdercoal in coal mills, before being blown by compressed air into the furnace and burned at temperatures ranging between 1300 and 1600 °C, depending on the type of boiler in question.

WhatsApp)

WhatsApp)