Grinding Balls, ADI/Forged/Casting Grinding Ball, High ...

Factory and head office: dongbin0815 Beijing office: +86 10 Project Director: Jason rongmaojason Sales Manager:Tanya rongmaotanya RD Engineer: rongmaoservice

WhatsApp)

WhatsApp)

Factory and head office: dongbin0815 Beijing office: +86 10 Project Director: Jason rongmaojason Sales Manager:Tanya rongmaotanya RD Engineer: rongmaoservice

PULVERISETTE 4 classic line; Software MillControl premium line; Ball Mills. PULVERISETTE 0 ; PULVERISETTE 23 ; Cutting Mills. PULVERISETTE 19 variable speed rpm; PULVERISETTE 19 variable speed 50700 rpm; PULVERISETTE 15 ; PULVERISETTE 25 ; PULVERISETTE 25/19 ; Knife Mill. PULVERISETTE 11 ; Rotor / Beater Mills. PULVERISETTE 14 premium ...

The Jaw Crusher BB 300 is used for the rapid, effective crushing and precrushing of mediumhard, hard, brittle and tough materials. Its variety of materials offered, including heavymetal free steel and its efficiency and safety makes the BB 300 ideal for sample preparation in laboratories and industrial plants.

On top of this, many companies treat different parts of their mining operations as independent units. It''s not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant.

Ball Mill PINION SHAFT BEARINGS. Pinion shaft bearings are of the SKF antifriction type mounted in a common twin bearing assembly. Bearings are fixed in place so that the pinion shaft of the mill is always in alignment with the drive components. Vbelt driven mills are furnished with an outboard bearing of similar construction.

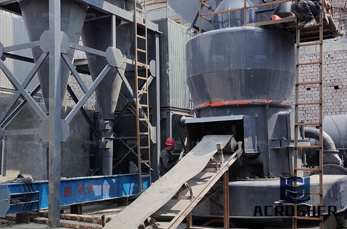

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work . The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials. Depending on the desired final fineness, the grinding can be ...

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

Show Name Dates Location Website; Houstex Trade Show (SME) February 2628, 2019: Houston, TX: ISA Convention: April 69, 2019: Houston, TXD: Amerimold Trade Show

May 26, 2018· My dad helped me rebuild the ball mill so that is far better and can actually crush ore by the bucket load. Help me make videos by donating here: https://

Ball end mills have a rounded nose and create a roundbottomed groove in milling tasks. Also known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent ...

Unused 5'' diameter X 6'' long Steel Lined Ball Mill, manufactured by Patterson Industries, Type D, nonjacketed, with AR400 steel liners. Includes 30 HP, 3 phase, 60 Hz, 230460 V, 1725 RPM motor. Mill drive is integrally coupled to horizontal parallel shafted helical gear reducer.

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected ...

This article will take you to explore the similarities and differences between ball mill and ag mill, to help you choose the appropriate grinding equipment more conveniently. 06:05:08. 265. 0. More. HOT. 1. Summary of Gold Cyanidation Methods. . 3154. 996. 2. 6 Factors That Influence Gold Leaching Effects ...

Ball Mill Design Parameters. Size rated as diameter x length. Feed System. One hopper feed; Diameter 40 – 100 cm at 30° to 60° Top of feed hopper at least meter above the center line of the mill.

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Jul 08, 2020· ALPA POWDER Case: ITC 3 Magnesium oxide Ball Mill and Classifying Production Line Duration: 1:34. ALPA POWDER 1 view. New; 1:34. Refurbishing Lathe Chucks Duration: 39:08.

Ball End Mills have a hemispherical tip used to machine rounded details, such as the metal bearing grooves found in machines. Also called Ball Nose End Mills, they are used extensively in manufacturing tools dies, and machining complex three dimensional contours with a smooth finish. Ball End Mills are very durable, and come with an array of surface coatings tailored for milling a wide range ...

SpeTool Tapered Ball Nose End Mill 1/4" X 3" with Ball Nose for CNC Machine Engraving Carving Bits Woodworking HSi Coated by SpeTool 16 . 99

Jan 01, 2016· Based on these test results, a m diameter × m length SAG mill and a m × m ball mill were installed for commercial operation in closed circuit with a hydrocyclone. The SAG mill had a 6–8% ball charge and the power consumption was 8 kWh/t, which agreed well with the expected value. Problems.

FRITSCH PULVERISETTE 7 premium line Planetary Ball Mill In Planetary Ball Mills, the comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls. PULVERISETTE 7 premium line: As an extension to the existing classic line of Planetary Mills, FRITSCH now offers for the ...

Unblocked Games here at Mills Eagles! Thousands of unblocked games for you to play.

WhatsApp)

WhatsApp)