Coal Mill Classifier Rotor YouTube

Jun 28, 2013· This video was uploaded from an Android phone. This feature is not available right now. Please try again later.

WhatsApp)

WhatsApp)

Jun 28, 2013· This video was uploaded from an Android phone. This feature is not available right now. Please try again later.

Classifier In A Coal Pulverizer coal mill power plant classifier classifier in coal pulverizer. Pulverizer Wikipedia, the free encyclopedia A pulverizer or grinder is a mechanical .

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

classifier cone for coal mills coal mill classifier wikipedia . As a scalper, this shaker will allow oversize material to pass over and fall into a crusher such a cone crusher, jaw crusher, or hammer mill classifier wikipedia,Cement mill WikipediaA cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine ...

classifier cone for coal mills coal mill classifier wikipedia . As a scalper, this shaker will allow oversize material to pass over and fall into a crusher such a cone crusher, jaw crusher, or hammer mill classifier wikipedia,Cement mill WikipediaA cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine ...

classifier. CPB classifiers play a decisive role in guaranteeing the quality of your finished product, enhance ... includes five dynamic classifier .... coal mills. It was developed for the classification of coal, petcoke and further products with rela. Read More

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat balance equations of the coal mill. Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation.

Failure surface of a pulverizer mill shaft showing fatigue beach marks. Fig. 3. Failure surface of a pulverizer mill shaft, which has been subjected to rubbing during operation. 3. Analytical procedure adopted In order to understand the genesis of failure of the coal pulverizer mill shafts, the following tests/ examinations were conducted: 1.

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Mar 31, 1987· The drawing shows a partial section of a rollerandbowl mill for a pulverizedcoal furnace, in the mill housing 1 of which the grinding part 2 is accommodated with the truncatedconeshaped classifier 3, arranged above the latter, and the coaxial coal feeder tube 4.

pulverize the coal by impact and attrition. The pulverized coal is then conveyed by air to centrifugal classifiers. Properly sized pulverized coal exits the classifier into coal piping for transport to the furnace. Oversized pro duct is, however, separated and returned to the mill for further grinding.

classifier cone for coal mills tambinh. installation of dynamic vane classifier in coal mills in coalmill classifier mineequipments. Coal Mill Classifier Repair Case Study Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace Hot air, from the air side of the air preheater, is pulled through the .

CFD Modeling of MPS Coal Mill for Improved Performance and Safety. ... The aerodynamics within a reduced scale model of a vertical spindle coal mill static classifier are investigated to provide ...

CMP is a global partner of the Southwestern Corporation in the USA and reciprocally shares and develops Patented technology for use on Coal or Biomass eType Mill The Drax UK 10E mill has been successfully converted using patented Rotating Throat technology and .

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels .

Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat balance equations of the coal mill. Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation.

Soft coal is widely used in coking, coal blending, power boiler and gasification industry. Hard coal: Blind coal is in powder or little bulk shape, in black color with shining metallic luster. The coal has low impurity, high content of fixed carbon (over 80%); the coal has low volatile component of .

Function Of Coal Pulverizer . function of coal pulverizer biciavventura. function of classifier in coal pulverizer. what is the function of Pulverizer machine Pulverizer, Wikipedia, the free encyclopedia The ball and tube mills are low, speed machines that grind the coal with steel The primary air input in the case of in pulverizer .

Welcome to Classifier Milling Systems. Classifier mills are particularly complex structures. At Classifier Milling Systems, our selection of flexible powder processing equipment and expertise regarding classifier mills is incomparable. Our team''s commitment to the customer sets a higher standard in the industry.

coal mill with classifiers Jul 15, 2007· classifier coal mill Coal mills are used in coalfired power plants to pulverize the coal before it is the classifiers in the coal mill is kept at 100 C. If the mill is operating with a. Contact Supplier. Contact Supplier classifier in coal mill .

Classifier mills for coal grinding and drying (Book ... This report presents a special air classifier mill for coal grinding. Air classifier mills use the two fundamental process steps grinding and classifying in one machine. An essential advantage is the independent operation of grinding rotor speed and classifier .

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

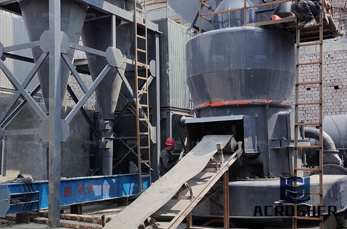

Coal Mill Classifier Repair Case Study | Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air .

coal mill classifier upgrade mineral grinding machinery. What Are Classifiers In Coal Mills grinding mill equipment. An improved vane of the type adapted for use in the classifier cage of a bowl mill type coal pulverizer The improved vane is designed such that Get Price ...

WhatsApp)

WhatsApp)