capacity which effect the capacity of mill – Grinding Mill ...

Home > Products > > cylindrical grinding machine dimensions 810*100 x850 mm capacity which effect the capacity of mill » Learn More Operations Management Ch. 5 Strategic Capacity .

WhatsApp)

WhatsApp)

Home > Products > > cylindrical grinding machine dimensions 810*100 x850 mm capacity which effect the capacity of mill » Learn More Operations Management Ch. 5 Strategic Capacity .

Effect of chute level on mill capacity . By Geoffrey Alan Kent. Get PDF (207 KB) Abstract. IN MANY FACTORIES, the feed chute of the first mill is operated with a high chute level for the purpose of maximising the cane rate through the mill. There is a trend towards trying to control chute level within a small control range near the top of a ...

Oct 21, 2014· Kent, Geoff (2013) Effect of chute level on mill capacity. In Hogarth, D (Ed.) Proceedings of the 28th International Society of Sugar Cane Technologists (ISSCT) Congress. The International Society of Sugar Cane Technologists / Sociedade dos Tecnicos Acucareiros e .

Effect of circulating load and classification efficiency on HPGR and ball mill capacity

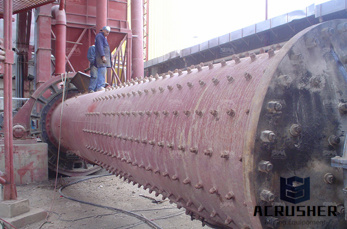

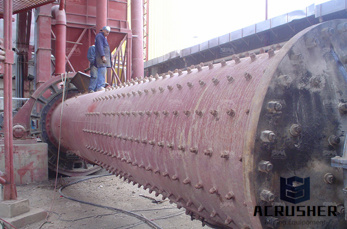

The production capacity of largediameter mill is high, and the power consumption of powder mill is low (because the ratio of the weight of the cylinder to the weight of the mill is small, the work required to overcome the friction is less).Long too short, product fineness difficult to meet the requirements, long too long, increase power ...

Aug 18, 2019· Factors That Affect Ball Mill Grinder Capacity And Quality 7 factors that affect the output of ball mill machine The grain size of raw material. Since the vertical kiln cement plant uses the small ball mill, the grain size of raw material can greatly affect its capacity and quality.

Sep 10, 2018· Answer: Good question. In the production capacity calculation formula, we are using product SAM to calculate the daily production capacity. Therefore, if you are adding finishing operation SAM, manual work (like marking, ironing) SAM, into the total garment SAM, those workstations will be part of the calculating factory capacity working hours.

Factors that affect ball mill grinder capacity and. ball mill grinder is the important equipment during the production of cement its capacity and quality even can directly affect the effiency of whoile production line 7 factors that affect the output of ball mill machine the grain sie of r. Read More

A low capacity utilization rate will result in a decrease in price because there are excess capacity and insufficient demand for the output produced. Economies with a capacity ratio of much less than can significantly boost production without affecting the associated costs.

Calculate Ball Mill Grinding Capacity. Previous Next. View Larger Image. The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of ...

Mill Capacity Calculations. There are a large number of formulae for the calculation of the capacity of a milling tandem. Hugot gives the following formula: A = c·n·√N·(·n·D)·L·D 2 /f. where c. is a factor dependent on the cane preparation equipment, c

Apr 28, 2020· Idle capacity is the remaining amount of capacity left in a company after productive capacity and protective capacity have been eliminated from consideration. Productive capacity is that portion of a work center''s total capacity needed to process currently scheduled production, while protective capacity is additional capacity held in reserve to ensure that a sufficient quantity of parts .

15 points Read the passage. I''m not satisfied to have fifty percent of our steelmill capacity unused. I''m not satisfied when the United States had last year the lowest rate of economic growth of any major industrialized society in the world. . . .

A multipleeffect evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water. In a multipleeffect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the ...

Nov 01, 2006· The effect of liner/lifter profile on kinetics of batch grinding and the milling capacity in general was assessed using monosize quartz material of 30 × 40 mesh (−600 + 425 μm) as feed. The liner profiles tested were, (i) bevel with 60° lifter face angle to represent the new liners, (ii) bevel with 45° lifter face angle to represent the ...

6 Ventilation: When the ventilation inside the mill is good and the wind speed is appropriate, the production capacity of the mill is high. The closed circuit is generally ~ m/s, and the open circuit is generally ~ m/s.

Since man began beneficiating ores, a limited number of factors influenced the type of treatment. The ore itself has always been a factor. The first form of concentration was probably hand sorting, and the grade of concentrate and recovery had to be considered from the start. Five of the principal factors having an effect on the power consumption per unit of capacity are: Hardness of the ore ...

1. J Sports Sci. 2018 Jul;36(14):. doi: / Epub 2017 Dec 1. Effects of the Nordic Hamstring exercise on sprint capacity in .

Capacity utilisation is a measure of the extent to which the productive capacity of a business is being used. It can be defined as: The percentage of total capacity that is actually being achieved in a given period When a business is operating at less than capacity, it is said to have "spare ...

Jul 24, 2019· 2. The feed size: the feed size is too big, and it is easy to block the feed port, and it is difficult to achieve grinding. But the feed size is too small, not easy to form a layer of materials, resulting in a clash between grinding roll and grinding ring, so it can affect the capacity of the Raymond mill.

This can reduce mill capacity and air classifier performance. Particle surface chemistry can affect many material properties that affect flow, including stickiness, affinity for water, and tendency to accumulate electrostatic charge. The flowability of the feed material dictates which type

Mar 25, 2020· The capacity utilization rate is a metric used to measure the rate at which potential output levels are being met or used. It provides insight into the overall slack that is in an economy or a ...

E. Capacity affects organizations'' images. E. Capacity affects organizations'' images. Which of the following is the case where capacity is measured in terms of inputs? A. steel mill B. electrical power plant C. restaurant D. petroleum refinery E. airline. C. restaurant. Unbalanced systems are evidenced by: A. topheavy operations.

It is the sound of rising costs by the hour both from the downtime itself and from maintenance costs. Optimising the capacity of your SAG mill is crucial to avoiding downtime and liner wear and damage. With variances in mill ore feed rate, mill speed and slurry density, critical impacts can occur in your SAG mill.

WhatsApp)

WhatsApp)