cost Fly Ash Brick Project Feasibility Study ...

View Homework Help cost from MANAGEMENT 131 at Air University, Islamabad. Fly Ash Brick Project: Feasibility Study Using CVP Analysis By: .

WhatsApp)

WhatsApp)

View Homework Help cost from MANAGEMENT 131 at Air University, Islamabad. Fly Ash Brick Project: Feasibility Study Using CVP Analysis By: .

Project Report for fly ash brick making machines. PROJECT REPORT FOR FLY ASH BRICKS MANUFACTURING UNIT Machinery value bricks : Customer scope: Wooden pallets: 3''x2''x1" with 4" leg – 100 No''s,00, ... OUR Fly ash brick making plant has been designed to manufacture fly ash bricks with Eco friendly ... much better clay brick.

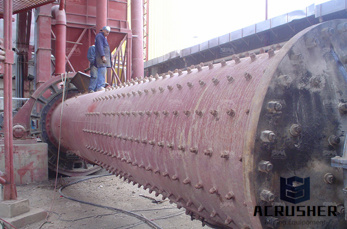

bricks plant project report pdf filterkitit. Project Report for fly ash brick making machin IBM Fly ash Brick Making PlantTechnical Features: OUR Fly ash brick making plant has been designed to manufacture fly ash bricks with Eco friendly technology It is a simple cost effective technology available in the Country The heart of the plant is ...

Fly ash Bricks ( FALG) manufacturing Process . Process of Manufacture: Fly ash, Hydrated lime, Quarry dust and gypsum are manually fed into a pan mixer where water is added in the required proportion for intimate mixing.

project report paver block manufacturing plant cost. what is cost of paver bricks/project report of paver block ... · what is cost of paver bricks/project report of paver block unit ... lying type,fly ash brick making plant fully automatic,viberation table for interlock tiles/pavers,pvc/ plastic mould for Tile ... >>Chat Online; cost of jk tile and pavers manufacturing machine

The severity of sulphate attack depends upon amount of soluble sulphate present, permeability of fly ash bricks, concrete mortar, proportion of C 3A present and duration for which the building components in quantity remains damp. If pure water free of sulphate is used for manufacturing of fly ash bricks

IBM Fly ash Brick Making PlantTechnical Features: OUR Fly ash brick making plant has been designed to manufacture fly ash bricks with Eco friendly technology. It is a simple cost effective technology available in the Country. The heart of the plant is an indigenously designed, a relatively low cost high productivity machine.

aac block project report pdf . aac brick manufacturers project report pdf BINQ Mining. · project report of Dearye autoclaved fly ash brick In this project, Illinois coal fly ash was substituted Used Plant For Aac Bricks In NasikAutoclaved Aerated Concrete (AAC) blocks are made of fly ash, aluminium powder and water. ... reduces the cost of the project.

Project Report on Manufacturing of Bricks Compiled by . Jitendra Kumar Sinha JPRMS CO. ... This project report is based on the technical financial data and information furnished by the ... wastage materials like fly ash in bricks making, Promoting deep mining of clay instead of surface

Project Report for fly ash brick making machines. ... Concrete Plant Project Report plasmarau project report on concrete blocks plants pdf This report is a revision of the report "Environmental Life Cycle Inventory of Portland concrete exiting the plant gate, (ii) concrete block exiting the manufacturing plant, and (iii) [1] The Portland ...

PROJECT PROFILES : Manufacturing Sales related Businesses: Name of the Project Profile. MS Word File format. PDF File format. AGARBATTI MAKING. MS Word File: PDF File: ... FLY ASH BRICKS. MS Word File: PDF File: LIQUID BLUE. MS Word File: PDF File: VERMI COMPOSING. MS Word File: PDF File: FRUIT JUICES.

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C or class F fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freezethaw cycles.

Fly Ash Bricks PROJECT REPORT. Fly Ash bricks are made of fly ash, lime, gypsum and sand. These can be extensively used in all building constructional activities similar to that of common burnt clay bricks. The fly ash bricks are comparatively lighter in weight and stronger than common clay bricks.

Fly Ash Bricks provides a high level of moisture resistance. It''s very economical, cost effective, nil wastage while transporting and handling. Fly Ash Bricks is available in various sizes. These qualitative bricks have high compressive strength and absorb low water. As a whole it is a good project for entrepreneurs to invest.

Major areas of fly ash utilization established through continual RD efforts in the country are Building materials as BRICKS, blocks, tiles, etc. Cement and cementitious binders and Special grade materials such as oil well cement, sulphate resistant cement, insulating and low density building products.

High Performance Bricks from Fly Ash . Obada Kayali. 1 . 1. School of Aerospace, Civil and Mechanical Engineering, University of New South Wales at The Australian Defence Force Academy, Canberra, ACT 2600.

This is to certify that the dissertation entitled " FLY ASH BRICKS " has been carried out by Pratik Solanki, Dipti Singh, Jigar Sutariya, Kuldeep Thakur, Ravikumar Sukla under my guidance in fulfillment of the degree of Bachelor of Engineering in Civil (8th Sem.) of Gujarat Technological University, medabad during the academic year

The summary of my book is reports the findings of an investigation done on bricks made using fly ash (FA), quarry dust (QD), and billet scale (BS) by nonconventional method.

PROJECT PROFILE ON CEMENT CONCRETE HOLLOW BLOCKS PRODUCT : Cement Concrete Hollow Blocks NIC CODE : 26959 (based on NIC 2004) ... hollow blocks being usually larger in size than the normal clay building bricks and less mortar is required, faster of construction is achieved. ... 2 Preparation of the project report 1 month

bricks fly ash bricks have high affinity to cement mortar though it has smooth surface, due to the crystal growth between brick and the cement mortar the joint will become stronger and in due course of time it will become monolithic and the strength will be consistent. 8. PRODUCTION CAPACITY PER ANNUM: Quantity: 24 lakh bricks total value Rs.

Dec 29, 2015· W13543 FLY ASH BRICK PROJECT: FEASIBILITY STUDY USING CVP ANALYSIS S. K. Mitra and Shubhra Hajela wrote this case solely to provide material for class discussion. The authors do not intend to illustrate either effective or ineffective handling of .

Flyash bricks have a bright future in the country in the form of increasing number of takers and brick making plant providers who are offering machines equipped with technology and quality. Thus, due to demand it is a good project for entrepreneurs to invest.

Detail Project Report On Brick Manufacturing. Project profile on fly ash building brickshere are around 25 falg bricks manufacturing units functioning in the state of orissa and many more prospective entrepreneurs are going for the said project.

How to set up a Fly ash Brick Manufacturing Unit in India . Fly ash Brick manufacturing is profitable business in India. The basic Needs to setup a Fly ash Brick manufacturing unit in India are . 1. Minimum 50 cents to 1 acre Land ( factory campus) 2. It should be situated in .

WhatsApp)

WhatsApp)