Coal Pulverizer Maintenance Improves Boiler Combustion

Nov 30, 2015· Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy. Here are some solutions for overcoming commonly identified combustion .

WhatsApp)

WhatsApp)

Nov 30, 2015· Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy. Here are some solutions for overcoming commonly identified combustion .

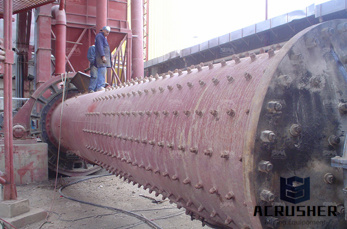

Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP BowlMill Coal Pulverizer.

• Combustion engineering and consultation engineering and design RV''s manufacturing team has decades of experience fabricating power plant equipment. ... All coal nozzles are specifically designed or validated to match coal characteristics and pulverizer primary air flow. Complete coal nozzle assemblies with coal

Combustion engineering grinding mills coal . Combustion engineering coal mill parts. coal mill parts combustion engineering 783rp bowlmill coal pulverizer enclosed chamber with wear resistant plat the hammers impact on the coal, crushing it against the plat further pulverization is achieved as the smaller coal particles are ground through attrition against each ...

Coal Pulverizers. RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering, Foster Wheeler, Babcock Wilcox, and Alstom bowl mills. Our mill body wear liners, deflector liners, journal liners, and pulverizer rolls are engineered to offer the longest wear life with the lowest risk of catastrophic failure.

Combustion Services Combustion Services remain the core work at Exothermic Engineering. Whether it is burner design, burner modification or burner testing, burners are at the center of our interests. Coal pulverizers, coal classifiers, crusherdriers and coal conduits merit similar attention.

Combustion Engineering Raymond Bowl Mill. Combustion engineering raymond engineering 783rp bowlmill coal pulverizer enclosed chamber with wear resistant plat the hammers impact on the coal, crushing it against the plates, get a price, raymond mill,raymond roller mill,raymond grinding mill, application of raymond mill raymond mill is also called ...

Sep 16, 2019· COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS NFPA 85 Code (Boiler and Combustion Systems Hazards Code), Combustion Control, Oxygen Trim, Control of Air and Coal Flow into the Boiler, Matching Boiler Firing Rate Demand to Electrical load, NOx and SOx Control, Burner Management Systems, Boiler Permissive Starting Logic and Protective Tripping Logic, and .

combustion engineering coal pulverizer design . Combustion Engineering 783RP BowlMill Coal coal pulverizer designs are Vertical Roller. Mills. Figure 2 shows a cutaway Read more. 1 Inerting System Design for Medium Speed Vertical Spindle Coal This design guide has been prepared to address pulverizer inerting for vertical spindle, Examples of ...

The coal pulverizers reported on here are 783 RP (roll pressure) and 823 RP combustion engineering (CE) bowlroller coal pulverizers (bowl mills) installed at the State Energy Commission of Western Australia (SECWA) power stations. This paper reviews the design philosophy, operational principles, and system dynamics and establishes the

Pulverizer Design Coal: The pulverizer system should be designed to accommodate the fuel with the worst combination of properties that will still allow the steam generator to achieve the design steam flow. Three fuel properties that affect pulverizerprocessing capacity are moisture, heating value, and HGI, as discussed earlier.

Pulverizers 101 Part I POWER Magazine. coal pulverizer design china. Pulverizers 101 Part I The design capacity of that same pulverizer is 135000 pounds per hour with fuel that is 55 HGI 34inch raw coal maximum size and 7 moisture The pulverizer will then have the capability to produce pulverized coal that is 70 passing 200 mesh fineness Figure 2 red line This is commonly expected performance ...

Improving coal pulverizer performance and reliability. Coal crusher raw coal bunker to boiler furnace raw coal feeder exhauster hot air motor coal pulverizer figure 1 simplified diagram detailing a directfired coal burning system. 1 epri study on large coal fired utility boilers greater than 600mw using pulverizers with capacities greater than 50 tons per hour combustion engineering 783rp ...

Tue Combustion Engineering Coal Pulverizer Design . Types of pulverizer mill in power plants sandpalmdoorscoza. Power generation industry studies have The four most common types of coal coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway Get Price fineness of coal in coal mill Coal mill pulverizer in thermal power plants coal mill design finess of coal mill 12 Sep 2012 ...

Charpente Rp Combustion Engineering. combustion engineering pulverizer mill parts – Grinding Mill Air Preheater Company Product Category ALSTOM Power. The Alstom HP Coal Pulverizer is the culmination . 1918 Combustion Engineering . Obtenir le prix . Combustion Engineering trainingbagus. read more

Jul 31, 2011· Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of ...

Combustion Engineering Pulverizer Mill Parts. Combustion Engineering Grinding Mills Coal Farmine. Combustion engineering coal mill mill parts engineering 783rp bowlmill coal pulverizer enclosed chamber with wear resistant plat the hammers impact on the coal, crushing it against the plat further pulverization is achieved as the smaller coal ...

Babcock Wilcox (BW) is now applying its vast experience and knowledge of roll wheel and ballandrace pulverizers to provide quality replacement parts, services and inventory management programs to Combustion Engineering (CE)type mills / pulverizers. Since 1867, BW has set the standard for proven high availability, reliability and low maintenance on its boilers, pulverizers and other ...

Coal pulverizer design and operation is an important element integral to the long term success of Low NOx combustion systems The increased use of Low NOx burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous ...

Design Calculation For Raw Mill And Coal Mill. Coal Ball Mill Design Calculations Image Results Free Quote coal ball mill design calculations hotelmayalretreat calculation of hot air required for a coal mill For example a pulverizer mill is used to pulverize coal for combustion in the capacity of this coal is 1 2 J/g/C process which are justified by practical plant design

Combustion Engineering Coal Mill Parts. Combustion engineering pulverizer mill parts combustion engineering 783rp bowlmill coal get priceulverizer wikipedia pulverizer or grinder is a mechanical device for the grinding of many different types of materialsor example, a pulverizer mill is used to pulverize coal for combustion in more.

combustion engineering coal pulverizer. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply ...

Combustion Engineering, Babcock Wilcox, and Riley Stoker Corp. are major manufacturers of coal pulverizing equipment. The four most common types of coal pulverizers are: BallTube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube.

Combustion Engineering Pulverizer, used coal pulverizers, A fire broke out in the discharge piping of a coal pulverizer in a 110 MW coalfired power, American Pulverizer has the engineering, ....

WhatsApp)

WhatsApp)