MinetoMill® optimization of aggregate production ...

Request PDF | MinetoMill® optimization of aggregate production | MinetoMill® optimization is a total systems approach to the reduction of energy and cost in mining and mineral processing ...

WhatsApp)

WhatsApp)

Request PDF | MinetoMill® optimization of aggregate production | MinetoMill® optimization is a total systems approach to the reduction of energy and cost in mining and mineral processing ...

Jul 21, 2020· Regulatory approvals have been granted to IAMGOLD for the mine''s environmental assessment and closure plan, as well as receiving permits related to its fish habitat and tailings management plan. Other permits are being applied for related to fish collection, access roads, dams and reconnections, industrial sewage and aggregate sourcing.

What is aggregate? Aggregate is sand, gravel and crushed stone in their natural or processed state. In Minnesota, aggregate companies mine glacial sand and gravel deposits and quarry limestone, quartzite, granite and other igneous rock formations. Aggregate is .

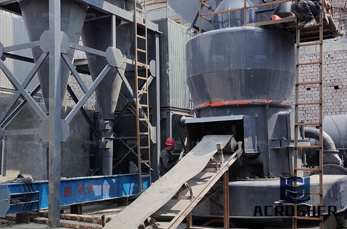

Abstract. MinetoMill optimization is a total systems approach to the reduction of energy and cost in mining and processing. Developed at the Julius Krutschnitt Mineral Research Center in Queensland, Australia, the MinetoMill approach attempts to minimize energy consumption through optimization of all steps in the size reduction process.

Aggregates: Mineral information, data and localities. In a stirred media mill, the mill body is static and the charge motion is created by an agitator such as a rotating spiral or impeller. We provide both original body liners and spiral/impeller liners designed as a system for each of the mill sizes of ''s extensive range of stirred media mills.

Ball Grinding MillAggregate Crushing Plant. Ball Grinding Mill When it comes to ball Grinding Mills, everyone is no stranger. As a largescale mine Grinding Mill, it is widely used in various industries because of its. Buyers For Bentonite Powder Equipment. Ball Grinding Mill When it comes to ball Grinding . Chat With Support

MineToMill Optimization of Aggregate Production – Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. Plant Sampling at Luck Stone Bealeton Quarry, MinetoMill .

MinetoMill Optimization of Aggregate Production. MinetoMill optimization is a total systems approach to the reduction of energy and cost in mining and processing. Developed at the Julius Krutschnitt Mineral Research Center in Queensland Australia the MinetoMill approach. Author Greg Adel Toni Kojovic and Darren Thornton Service Online

Coal Mine Ball Mill. Qty. Clutches Brakes BSFA 1000 Series Braking System ... Mining and Aggregate Series 2000 Helical Bevel Gear Drive. P7335BG Mud Pump Agitators. Qty. HOR Series Overload Clutch. P8138BG Mine Bowl Crusher. Qty. 700 Series Speed Reducers ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

A quarry is a place where rocks, sand, or minerals are extracted from the surface of the Earth. A quarry is a type of mine called an openpit mine, because it is open to the Earth''s type of mine, a subsurface mine, consists of underground tunnels or shafts.. The most common purpose of quarries is to extract stone for building materials.

Apr 30, 2020· MinetoMill optimization is a total systems approach to the reduction of energy and cost in mining and processing. Developed at the Julius Krutschnitt Mineral Research Center in Queensland, Australia, the MinetoMill approach attempts to minimize energy consumption through optimization of all steps in the size reduction process. The approach involves sampling and modeling of blasting and ...

Aggregate Stone Mining Bernalillo County HATTIE MINE 1 Shale and Clay NM Brick Co., Inc. PO Box 1804, Albuquerque, NM 87103 (505) Type of Operation: Surface Mine Status: Active Mining MSHA Number: Location: Sec 18 T9N R6E USGS Quad: Sedillo Mineral Estate: Private Land; NM Brick Co., Inc. Surface Estate: Same OSUNA PIT 2 Other

aggregate physical properties, and, in particular, gradation (size control). ... the mine. For example, excessive knobs and depressions on the surface of a stone ... and attrition mill. The log washer (Figure 515) commonly is used in wet operations to agitate

Dec 01, 2005· The introduction of aggregate stemming was therefore expected to also benefit the mill in terms of throughput as the RunofMine (ROM) material in the stockpile should have more fines. The extent to which the stemming has actually improved the mill performance was unclear and analysis was clearly warranted.

Mine To Mill Aggregate. The resulting increase in concentrate production in 1999 was estimated to be worth US25M. Dr Kojovic also led a minemill initiative to address an expected shortfall in 2002 production post the completion of a US100M VIP project in late November 2001.

The Hanson Aggregates LLC''s Mill Creek Quarry (hereinafter "Mill Creek Quarry"), located in Johnston County, Okloma, is an "exempt mine 1" for which an initial application has been filed with Okloma Department of Mines as of August 1, 20 11.

Mine To Mill Aggregate. optimization is a total systems approach to the reduction of energy and cost in mining and at the julius krutschnitt mineral research center in queensland, australia, the minetomill approach attempts to minimize energy consumption through optimization of all steps in the size reduction process.

Apr 08, 2013· The Doe Run Company Buick Mine/Mill Iron County, S26, T34N, R2W 1. Production Limitations A. The Doe Run Company Buick Mine/Mill shall not process more than 296,296 tons per year of aggregate in the crusher (EP101) in any consecutive 12month period. B. Attachment A, or equivalent forms, such as electronic forms, shall be used

TS Manufacturing has been designing, manufacturing and installing quality bulk material handling systems for mining, aggregate, quarry, cement and many other industries for nearly 40 years. Our experienced engineering department utilizes the latest in CAD design software and is capable of working in 2D or 3D with nearly any file format.

In many mine to mill type studies (Simkus and Dance, 1998; Kojovic, 2005; Michaux and Djordjevic, 2005;Morrell and Valery, 2001 and many others) has been demonstrated the influence of the feed ...

assist DOE in assessing the applicability of the MinetoMill approach to the aggregates industry. 1. Implementation of MTM guidelines at Pittsboro has resulted in tangible improvements in productivity. It is clear that MTM guidelines represent an energy savings of around 5% (primary and secondary) and an overall energy savings of 1%.

AlOtaibi [26] who used steel mill (iron oxides) as fine aggregate in cement mortars, found that drying shrinkage was lower when using steel mill scale. He also showed that replacing 40% of sand ...

A secondary but important benefit to come out of the change in stemming practice has been the reduced wear in the gyratory crusher, resulting in a significantly longer period between relines. This paper compares the key mill performance indicators when the mine moved from drill cuttings to aggregate as stemming in the blast holes.

WhatsApp)

WhatsApp)